Maintenance and lubrication

To ensure trouble-free employment of BÜCO’s precision universal joints and precision shaft joints with friction bearings or brackets you should lubricate them at regular intervals. BÜCO’s precision universal joints with needle bearings are maintenance-free and, due to their permanent lubrication, are preferably used in machine components difficult to access.

Caution:

BÜCO’s precision universal joints and precision shaft joints are ready for use and are lubricated with a lithium saponified, extreme pressure lubricant on a mineral oil base.

Temperature range lubricant: from -30° to +125°C (permanent lubrication)

Peak temperature lubricant: maximum 140°C

Please use lubricants with the same specification for re-lubrification.

Lubricating points

Lubrication is required at least once daily for permanent operation at the lubricating points marked with arrows.

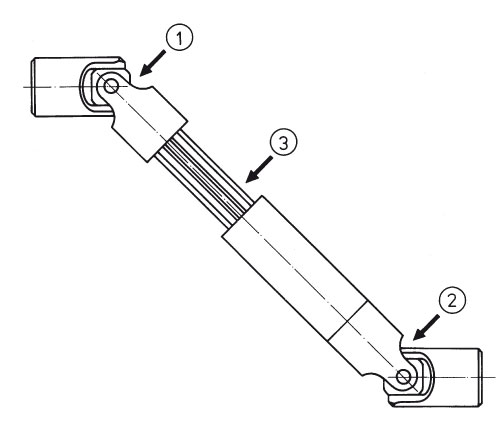

For friction bearings and bracket version this means all the sliding parts on the cube, the fork piece and bearing pins (1) and (2) as well as (3) for shaft joints the sliding parts of the extendable splined profile.

In harsh environments, the sliding parts should be protected against fibrous particles and steam by means of a folding bellow. Permanent self-lubrication for an indefinite time is achieved by filling the folding bellow with a lubricating grease.

Note:

Maintenance work should be carried out at regular intervals; preferably while carrying out maintenance work on other machine parts.

In such cases, we recommend that noise and backlash tests be conducted, or if the working noise and/or the backlash of the joint and profile parts deviate from the standard values.

Instructions for BÜCO’s precision universal joints with needle bearings:

BÜCO’s precision universal joints with needle bearings in accordance with DIN 808-W are used wherever high transmission performances together with precise load transmissions at high speeds (of up to max. 5.000 r.p.m.) are required.

Power transmission is through the center of the universal joint via a forged spider, whose four polished studs are contained in needle bearing bushes sealed off by sleeves. The special roller bearing grease is inserted during assembly and guarantees that BÜCO’s precision universal joints with needle bearings remain absolutely maintenance-free due to permanent lubrication.